BI tools for manufacturing are transforming the landscape of the production sector by providing critical insights and data-driven decision-making capabilities. As manufacturers face increasing pressures to optimize operations and reduce costs, these tools have become indispensable. They facilitate the analysis of vast amounts of data, enabling companies to identify trends and make informed choices that enhance productivity and profitability.

From dashboards that visualize key performance indicators to predictive analytics that forecast future trends, the evolution of BI tools reflects the growing complexity of manufacturing processes. Understanding the functionalities and benefits these tools offer is essential for any manufacturer looking to stay competitive in today’s fast-paced market.

Overview of BI Tools for Manufacturing

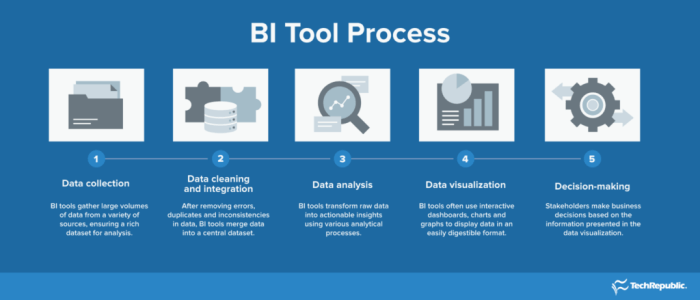

Business Intelligence (BI) tools play a pivotal role in the manufacturing sector by enabling manufacturers to make informed decisions based on data analysis and insights. As manufacturing processes become increasingly complex, the significance of BI tools has grown, facilitating improved operational strategies and enhanced productivity. The evolution of BI tools has been marked by the transition from traditional reporting systems to advanced analytics platforms that integrate real-time data, offering a profound impact on manufacturing processes.

Key functionalities essential in BI tools for manufacturers include data visualization, real-time analytics, and the ability to generate comprehensive reports. These features not only help in monitoring production efficiency but also assist in identifying bottlenecks and forecasting demand, making them indispensable for modern manufacturing.

Types of BI Tools Applicable to Manufacturing

Various types of BI tools are instrumental in the manufacturing sector, each serving distinct purposes to optimize operations. These tools include:

- Dashboards: These provide a visual representation of key performance indicators (KPIs) and metrics, allowing managers to monitor operations at a glance.

- Reporting Tools: Facilitate the creation of detailed reports, enabling manufacturers to analyze trends and make data-driven decisions.

- Data Warehousing: Centralizes data from various sources, making it easier to access and analyze for insightful decision-making.

- Predictive Analytics: Utilizes historical data to forecast future trends, helping manufacturers anticipate market demands and adjust production accordingly.

When comparing cloud-based BI tools to on-premise solutions, cloud options offer enhanced flexibility and scalability, allowing manufacturers to access data from anywhere, while on-premise solutions provide greater control over security and data management.

Benefits of Implementing BI Tools in Manufacturing

Implementing BI tools in manufacturing leads to significant improvements in operational efficiency. These tools streamline processes by reducing manual data entry and automating reporting, which ultimately saves time and resources. Moreover, BI tools enhance decision-making processes for manufacturing managers by providing timely insights that inform strategic planning and resource allocation.

For instance, manufacturers have reported cost savings through optimized inventory management and reduced waste. By analyzing production data, companies can minimize excess stock and improve resource utilization, leading to more efficient operations.

Challenges in Implementing BI Tools in Manufacturing, BI tools for manufacturing

Despite the benefits, manufacturers often face challenges when adopting BI tools. Common obstacles include a lack of skilled personnel to manage and interpret BI data, resistance to change among staff, and the complexities of integrating BI tools with existing systems.

Data quality and integration are paramount for successful BI implementation. Inaccurate or incomplete data can lead to flawed insights, undermining the effectiveness of BI tools. Additionally, organizational changes may be necessary to foster a data-driven culture that fully leverages BI capabilities.

Best Practices for Using BI Tools in Manufacturing

To maximize the effectiveness of BI tools, manufacturers should adhere to best practices for selection and implementation. Effective strategies include:

- Assessing Needs: Evaluate the specific requirements of the manufacturing environment to select the most suitable BI tools.

- Training Staff: Implement comprehensive training programs to ensure that employees are proficient in using BI tools to their full potential.

- Establishing Data Governance: Create policies for data management to maintain data quality and integrity across the organization.

A checklist for successful BI tool implementation should include evaluating current data systems, defining clear KPIs, and ensuring ongoing support for users.

Future Trends in BI Tools for Manufacturing

As technology evolves, several emerging trends are set to shape the future of BI tools in manufacturing. One significant trend is the increasing integration of artificial intelligence (AI) into BI platforms, enhancing their capabilities for data analysis and predictive modeling.

The table below summarizes current BI tools versus projected future developments:

| Feature | Current BI Tools | Future Developments |

|---|---|---|

| Data Processing Speed | Real-time processing | Instantaneous analytics with AI |

| User Interface | Static dashboards | Dynamic, customizable interfaces |

| Predictive Capabilities | Basic forecasting | Advanced predictive insights with machine learning |

Case Studies of Successful BI Tool Implementations in Manufacturing

Several manufacturers have successfully integrated BI tools, leading to improved operational metrics. For instance, a prominent automotive manufacturer enhanced its production efficiency by 20% after implementing a BI dashboard that provided real-time insights into assembly line performance.

Key performance indicators (KPIs) that improved post-implementation included reduced cycle time and increased output per hour. These case studies illustrate valuable lessons in leveraging BI tools effectively, emphasizing the importance of aligning BI strategies with overall business goals to achieve optimal results.

Concluding Remarks: BI Tools For Manufacturing

In conclusion, the integration of BI tools in manufacturing not only streamlines operations but also empowers managers to make strategic decisions backed by data. Although challenges exist in the implementation process, the long-term benefits, including improved efficiency and cost savings, far outweigh these obstacles. By embracing best practices and staying abreast of future trends, manufacturers can fully leverage the potential of BI tools to drive success in their operations.