RockHaul payload rating is a critical component in understanding the efficiency and capability of RockHaul systems. This concept not only defines how much weight can be safely transported but also emphasizes the importance of accurate payload assessments for operators in various industries. By grasping the significance of payload ratings, users can ensure optimal performance and safety across their operations.

You also can investigate more thoroughly about Mazda sports car tuning guide to enhance your awareness in the field of Mazda sports car tuning guide.

The intricacies of payload ratings are influenced by multiple factors, including vehicle design, materials, and operational conditions. With this comprehensive overview, we delve into the specifications, calculations, and real-world applications of RockHaul payload ratings, shedding light on their relevance in today’s industrial landscape.

For descriptions on additional topics like BlizzardLine winter truck, please visit the available BlizzardLine winter truck.

Understanding RockHaul Payload Rating

The concept of payload rating within the scope of RockHaul is fundamental for both users and operators. It defines the maximum amount of weight that a RockHaul system can safely transport, ensuring efficiency and safety during operations. A well-defined payload rating facilitates optimal resource management and operational planning, directly impacting productivity.

Payload ratings hold significant importance for users and operators, as they influence decision-making processes regarding equipment selection and load management. A thorough understanding of payload ratings allows operators to adhere to safety regulations while maximizing the economic benefits of transporting materials. Several factors play a crucial role in determining the payload rating of RockHaul systems, including vehicle design, material properties, and operational conditions.

RockHaul Payload Rating Specifications

The specifications of RockHaul payload ratings provide critical insights into the operational capacities of different models. Below is a detailed comparison of various RockHaul models and their respective payload ratings.

| Model | Payload Rating (lbs) | Operating Weight (lbs) | Volume Capacity (cubic ft) |

|---|---|---|---|

| RockHaul Model A | 10,000 | 15,000 | 50 |

| RockHaul Model B | 12,000 | 18,000 | 60 |

| RockHaul Model C | 15,000 | 22,000 | 75 |

These specifications are essential as they determine the operational efficiency of RockHaul systems. A higher payload rating typically translates to increased productivity, allowing operators to transport more materials in fewer trips, thus optimizing resource utilization.

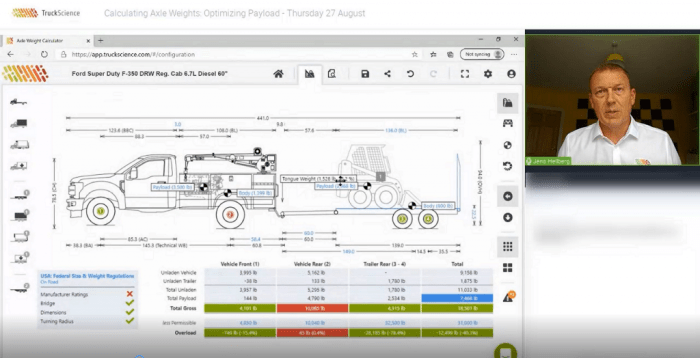

Calculating Payload Rating for RockHaul

Calculating the payload rating for RockHaul involves specific methods that consider various parameters. The primary formula used is:

Payload Rating = (Vehicle Gross Weight – Vehicle Empty Weight) – Safety Margin

To calculate the payload rating, follow these steps:

1. Determine the vehicle’s gross weight.

2. Measure the empty weight of the vehicle.

3. Subtract the empty weight from the gross weight to find the net weight.

4. Deduct a safety margin, typically around 10-15% of the net weight, to ensure safe operations.

For example, if a RockHaul vehicle has a gross weight of 20,000 lbs and an empty weight of 8,000 lbs, the calculation would be as follows:

– Net Weight = 20,000 lbs – 8,000 lbs = 12,000 lbs

– Deducting a safety margin of 10%: 12,000 lbs – 1,200 lbs = 10,800 lbs payload rating.

This demonstrates how various factors, such as vehicle design and operational conditions, can significantly impact the final payload rating.

Real-world Applications of RockHaul Payload Rating

RockHaul payload ratings are crucial across multiple industries, including construction, mining, and logistics. In construction, for instance, ensuring compliance with payload ratings can prevent equipment failure and enhance job site safety.

Case studies have illustrated successful implementations of RockHaul systems, showcasing their payload ratings:

– A mining operation increased productivity by 20% after optimizing their payload management using RockHaul systems, which allowed them to maximize weight limits safely.

– A construction company reduced costs significantly by efficiently managing their payload ratings, leading to fewer trips and lower fuel consumption.

Best practices for optimizing payload ratings in various applications include:

- Regularly training operators on load management techniques.

- Implementing a systematic approach to vehicle maintenance.

- Conducting routine inspections to ensure compliance with safety standards.

Innovations and Future Developments

Current trends in payload rating technology related to RockHaul include advancements in materials science and vehicle design, which enhance durability and efficiency. Innovations such as smart load monitoring systems are emerging, allowing operators to receive real-time data on payloads, thus optimizing operational performance.

Potential advancements may include the integration of artificial intelligence and machine learning to predict optimal payload ratings based on historical data. Additionally, regulatory changes could significantly impact future standards, prompting manufacturers to improve safety features and compliance mechanisms.

Comparing RockHaul with Competitors

A comparative analysis of RockHaul payload ratings against its top competitors highlights both advantages and disadvantages. RockHaul’s systems are noted for their robust design and reliability, but they may come at a higher initial cost compared to some competitors.

Below is a table detailing competitor specifications for easier reference:

| Competitor | Model | Payload Rating (lbs) | Operating Weight (lbs) |

|---|---|---|---|

| Competitor X | Model D | 11,000 | 16,000 |

| Competitor Y | Model E | 13,000 | 19,000 |

This comparative insight allows users to make informed decisions based on their operational needs and budget constraints.

Maintenance and Optimization of Payload Ratings

Sustaining optimal payload ratings requires diligent maintenance practices. Regular inspections and timely adjustments can prevent performance degradation over time.

A checklist for routine inspections related to payload ratings should include:

- Checking tire pressures and conditions.

- Inspecting load distribution and securing methods.

- Verifying compliance with safety regulations.

To enhance payload efficiency, operators should focus on optimizing load management practices, ensuring loads are evenly distributed and not exceeding the rated capacities. This approach not only promotes safety but also maximizes operational efficiency.

Last Recap: RockHaul Payload Rating

In summary, understanding RockHaul payload ratings is essential for maximizing operational efficiency and ensuring safety in transportation and logistics. Through careful consideration of specifications, innovative advancements, and maintenance practices, users can optimize their payload management strategies. As industries continue to evolve, staying abreast of the latest trends in payload rating technology will be crucial for future success.